Solid Timber Flooring Buckling, Tenting, and Panelisation

You must log in to ATFA as a member (with an active account) to view this content! Not a member? Join today. Username Password Remember

Home > Information Sheets > Sanding and Coating

Exclusive to ATFA’s members are the ever-popular extensive collection of information sheets, where we delve deep into the intricate world of timber flooring. From technical aspects of floors and decks, sanding, coating, to general tips, consumer awareness, OH&S, environmental concerns, and contractor awareness.

Equip yourself with the knowledge to make informed decisions, ensure best practices, and stay updated with the latest in the industry from over 100 technical documents – created by the ATFA for ATFA Members.

You must log in to ATFA as a member (with an active account) to view this content! Not a member? Join today. Username Password Remember

You must log in to ATFA as a member (with an active account) to view this content! Not a member? Join today. Username Password Remember

Belonging to the broader category of staining, liming or limewashing generally relates to the use of a technique that is designed to lighten or whiten a timber surface while maintaining the visual texture and character of the timber.

The long-term success of any flooring installation relies on quality substrate materials being used along with appropriate preparation and selecting fit for purpose products. Whilst we all may be familiaaA question commonly asked by those who have bamboo floors installed in their home is, can my floors be re-sanded and recoated in future years?

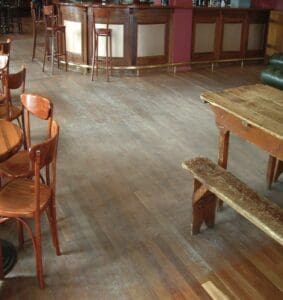

When it comes to site sanded and coated timber floors, there are various sheen level options available to choose from. The sheen level refers to the level of gloss or shine on the surface of the floor coating. Different sheen levels can have a significant impact on the appearance and overall aesthetic of the timber floor.

Some coatings will darken or yellow with time while other coatings may result in a floor becoming lighter with time.

Edge bonding can occur more so with some finishes if they penetrate gaps at board edges and act as an adhesive, and thereby bonding groups of boards together.

In this information sheet, we will look at the various aspects that can cause coatings to fry and provide us with a better understanding of how to avoid it, and also, should it occur, how to address it.

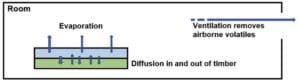

Outgassing, evaporation, diffusion and off-gassing are some of the terms used to describe the movement of volatile species from a coating that has been applied onto a surface.

Coating adhesion failure can be termed delamination, flaking, peeling, bond failure and various other terms.

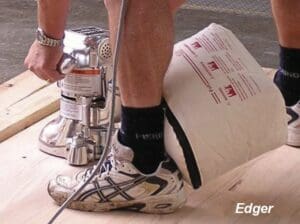

This information sheet outlines what owners should expect and factors to consider throughout the sanding and coating process for an onsite sanded and finished timber floor.

The practice of changing the colour or appearance of a timber floor via staining or colouring is not a new idea.

The renovation or recoating of prefinished flooring is becoming a more popular request among flooring contractors, particularly for floors in retail environments

Solid T&G timber floors are often re-sanded and coated, and this is part of the benefit of solid timber floors.

When working with cork, each job should be taken on its merits with differences from one site to another likely.

There are a number of aspects that need to be taken into consideration when existing timber floors are re-sanded and coated that the contractor should know and make the owner aware of.

When timber floors and sanded and coated many terms are often used that are at times difficult for those not specifically involved in floor sanding to understand.

When timber floors and sanded and coated many terms are often used that are at times difficult for those not specifically involved in floor sanding to understand.

Functional performance is generally related to after occupancy and includes factors such as wear resistance, slip resistance, ease of maintenance, edge bonding concerns, client health impact etc.

When it comes to solvent based satin finishes they need to be treated with more respect than gloss finishes and both the application technique and the coating environment become more important.