Solvent based satin finishes

When it comes to solvent based satin finishes they need to be treated with more respect than gloss finishes and both the application technique and the coating environment become more important.

Home > Information Sheets > Page 6

Exclusive to ATFA’s members are the ever-popular extensive collection of information sheets, where we delve deep into the intricate world of timber flooring. From technical aspects of floors and decks, sanding, coating, to general tips, consumer awareness, OH&S, environmental concerns, and contractor awareness.

Equip yourself with the knowledge to make informed decisions, ensure best practices, and stay updated with the latest in the industry from over 100 technical documents – created by the ATFA for ATFA Members.

When it comes to solvent based satin finishes they need to be treated with more respect than gloss finishes and both the application technique and the coating environment become more important.

Coated timber floors occasionally experience a condition known as ‘blooming’ which can be both aesthetically unsatisfactory and at times require remedial work such as recoating or even a full re-sand and recoat.

Ghosting traditionally relates to the appearance of lightly coloured boot prints that appear in a floor finish, usually some considerable time after the floor was coated.

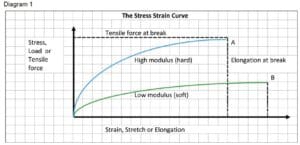

Mechanical properties are those physical properties that relate to strength, toughness and durability.

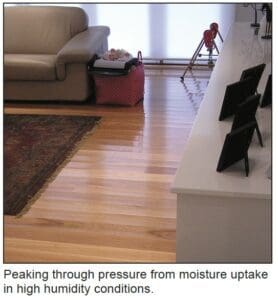

Cupping, peaking and crowning all relate to curvature across the board face – where the board edges are either higher or lower than the centre of the board. In the case of peaking and generally with cupping, the board edges are raised; and with crowning, board edges are lower.

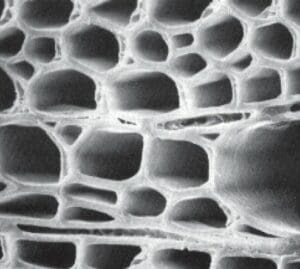

Cork is a durable and natural material with unique properties that make it desirable for flooring. The nature of cork (the bark of a tree) is that it has many enclosed air cells and contains the substance suberin that naturally repells moisture.

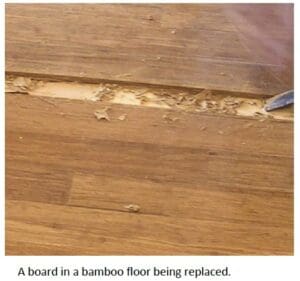

Firstly, it needs to be considered that there has been a tradition of solid timber flooring in houses being repaired. Old floors of perhaps 20 or 50 years have often had repairs for many reasons including squeaks, termite damage or water damage.

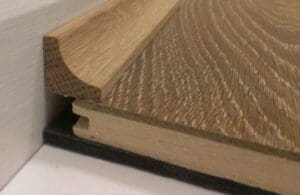

Traditionally, flooring was held in place by nailing it to the subfloor surface. Floating a floor is an installation system which originated in Sweden in the late 1970s with the development of Pergo, a reinforced laminate flooring product.

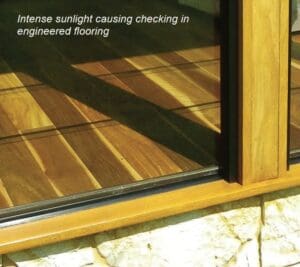

Firstly, we need to consider solid timber flooring and how it shrinks and swells with changing relative humidity. This is shown in the adjacent diagram with board expansion occurring under higher humidity conditions and board shrinkage under lower humidity condition.

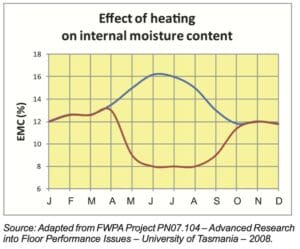

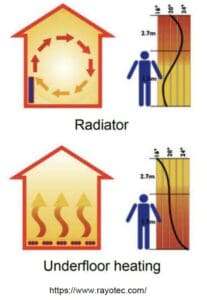

As the colder months approach us in autumn of each year, that familiar inkling to turn the heater on at night creeps back in. Before you know it, winter is in full swing and the heater is running for half the day and most of the night.

An essential part of timber deck design is to evaluate and include the necessary ventilation. This aspect is not always fully covered by timber supplier…

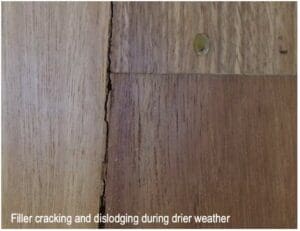

With solid timber floors the topic of gapping at board edges and the possibility of filling those gaps is a subject often raised.

Ever since there have been timber floors, seasonal movement has been observed where floors would shrink during drier weather and expand during more humid weather.

For as long as there have been timber floors there have been squeaks and it is generally accepted that many floors will make some noise when walked on.

When the wet weather has been more intense than previous years we have seen expansion pressure in floors take its toll.

Both wood-based and vinyl-based flooring can be installed over underfloor heating and in recent years owners in the cooler southern states of Australia and in New Zealand are more frequently including this heating option in their dwellings.

Australia has a long tradition of common names for species, and ‘blue’ gum is a prime example where there is a ‘blue’ gum in at least three states and each is a different species.

Boards with fewer and smaller features are sorted into one grade while those with more frequent and larger features would be sorted into another grade.

This information is provided for guidance when a timber floor has been inundated with mud and silt laden water

The hardness of timber is not directly related to how hard or easy the timber is to work with various tools but is a measure of the resistance of the wood to indentation. The hardness figures most commonly used are those obtained from the Janka test.