Timber Flooring Industry OH&S

There are many considerations an employer or contractor must be mindful of when it comes to Occupational Health and Safety.

Home > Information Sheets > Page 3

Exclusive to ATFA’s members are the ever-popular extensive collection of information sheets, where we delve deep into the intricate world of timber flooring. From technical aspects of floors and decks, sanding, coating, to general tips, consumer awareness, OH&S, environmental concerns, and contractor awareness.

Equip yourself with the knowledge to make informed decisions, ensure best practices, and stay updated with the latest in the industry from over 100 technical documents – created by the ATFA for ATFA Members.

There are many considerations an employer or contractor must be mindful of when it comes to Occupational Health and Safety.

When laying timber floors in older dwellings, as part of renovation work or repairs, there are two buildings products that require our special consideration.

Hazardous chemicals may be present in products and must be used safely in the work place. It is aimed to achieve this through workers having both knowledge of the hazards they pose and the means of handling these products safely.

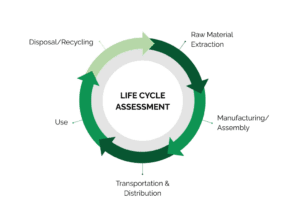

What is Life Cycle Assessment? – The long term environmental benefits of a timber floor

Australia is serviced by two timber certifying organisations, known as the Australian Forest Certification Scheme and the Forest Stewardship Council Australia

When you choose timber, you are not only selecting a beautiful individual floor made from a renewable resource, you’re also making a positive impact on climate change.

One option is to engage an ATFA Accredited Inspector and have your flooring concern inspected and reported on. You now have your report. This information sheet discusses the structure of the ATFA report and the options you have regarding it.

There are many different products available in the market that have the appearance of timber, however most are not ‘real’ timber, but provide the appearance of a timber floorboard.

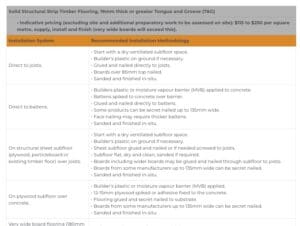

The following provides an overview of the different products and systems available when it comes to installing timber flooring products, as well as indicative variable market prices

These guidelines apply to any Timber floor. Following them will help your floor look good for longer between recoating and re-sanding:

In the not too distant past the sanding and finishing of a timber floor was a relatively straight forward task with a three coat system of gloss polyurethane being used in most instances.

There are many timber species used in timber floors, which provide us with a rich array of colours and grain patterns

If you believe you have a problem, firstly contact the company your contract of work was/is with, as they may have a right of rectification for minor repairs under Australian Consumer Laws.

In many Australian states, building regulatory authorities have developed a Guide to Standards and Tolerances for new building work

While larger businesses and those with overseas connections are very familiar with importation requirements, many small to medium businesses these days are making their own international arrangements.

An information sheet more suited to Queensland and NSW members, however, may have relevance in other locations from time to time. This is a snapshot in time examination of two closely related unseasonal weather conditions.

This information sheet provides a snapshot of licensing conditions across the various jurisdictions as at July 1st 2022

Watersplash is not defined by the MBIE but may be considered the intermittent minor wetting of parts of a floor in the normal use of a sanitary fixture or appliance.

New Zealand specific information sheet – E3/AS1 section 3.0 of the Building Code covers Watersplash with some suitable flooring materials listed in 3.1.1 Floors.

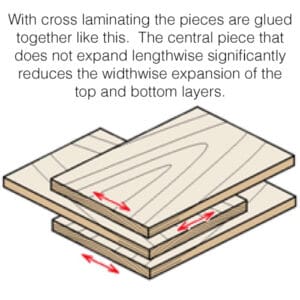

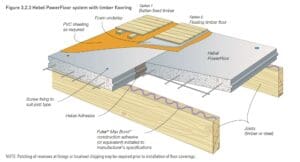

The popularity of prefabricated products has seen rapid growth over the last decade and is seen as a more rapid method of building than onsite construction.